Introduction

Dana Campbell, Sr. Applications Scientist, talks about onboard mixing with liquid handlers through aspirate-dispense cycles.

Onboard Mixing

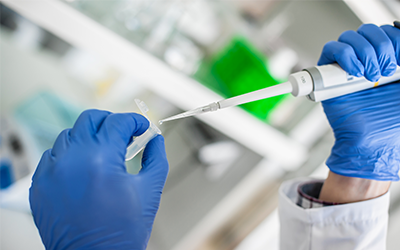

The contents of a solution can be mixed in a variety of different ways such as using shaking devices, manually vortexing, and even diffusion over time. However, the focus of this video is on a liquid handler or robot being used to perform pipette mixing through aspirate-dispense cycles.

There are a variety of situations when a liquid handler is tasked with performing onboard mixing of liquids by using one or more aspirate-dispense cycles. Sometimes, a mix step occurs after the dispense step and even in combination with a blowout volume. This is often to ensure that all the reagent is removed from the tip. Other times, the liquid handler is tasked with performing a thorough mix prior to aspirating.

A perfect example is performing serial dilutions. This application is commonly seen in the field when employing an 8 or 12 channel pipetting device that uses the same tips throughout the dilution series. If the target volume transferred is not accurate, or the mixing steps are not efficient, errors can quickly propagate across a plate.

Variables to Consider when Pipette Mixing

Four important variables to consider with respect to pipette mixing:

1. The Number of Mix Cycles

2. Aspirate and Dispense Speeds

3. The Volume of Liquid Mixed per Cycle

4. Tip Location during Aspirating/Dispensing

1. The Number of Mix Cycles

A good starting point is to use a minimum of four mix cycles. However, fewer cycles can be used if other variables are increased, such as the speed or mix volume. If you have a way to evaluate the effectiveness of the mixing process, the variables can be manipulated to efficiently mix in a timely manner with respect to the overall process.

2. Aspirate and Dispense Speeds

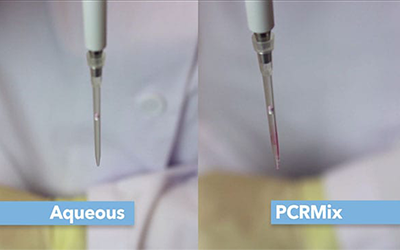

The speed of mixing may be increased or decreased depending on the liquid type. Controlling the speed of mixing so that it suits a particular scenario is important for ensuring an optimized process. Again, try to avoid forming bubbles and splatter during mix steps.

3. The Volume of Liquid Mixed per Cycle

The volume of liquid mixed per cycle depends on both the total volume in the well and the tip size. A good rule of thumb is to mix at least 50-75% of the total volume.

4. Tip Location During Aspirating/Dispensing

It is usually recommended that when mixing in a well, that the tip location is low during the aspiration step, and high during the dispense step – this helps with the vertical mixing within a well. Some advanced software can even control where the tip is in relation to the volume as it is being aspirated and dispensed in real-time. This liquid level tracking can help ensure that the tips are constantly moving in relation to the liquid level.

Conclusion

On-board robotic pipette mixing is often a critical step within a given protocol. Spending the appropriate time and effort to ensure effective mixing leads to improved assay performance and data integrity. It is important to make careful visual observations and consider these variables to ensure it is performing as it should.