- Products

- Bioprocessing Osmometers

- Clinical Osmometers

- Cell Line Development

- Artel Liquid Handling Verification

- Anaerobic Jar Systems

- CSF Cell Counter

- Bilirubin Testing

- Dairy Testing

- Applications & Industries

- Bioprocessing

-

-

Compliance & Conformity

Our portfolio of instruments, consumables and services are designed to help you maintain regulatory guidelines, ensure data integrity, and meet GMP requirements.

-

- Clinical

-

-

Compliance & Conformity

Our portfolio of instruments, consumables and services are designed to support clinical lab regulations, standards and with HIPAA data security in mind.

-

- Food & Beverage

- Bioprocessing

- Service & Support

- Resources

- Company

- Products

- Bioprocessing Osmometers

- Clinical Osmometers

- Cell Line Development

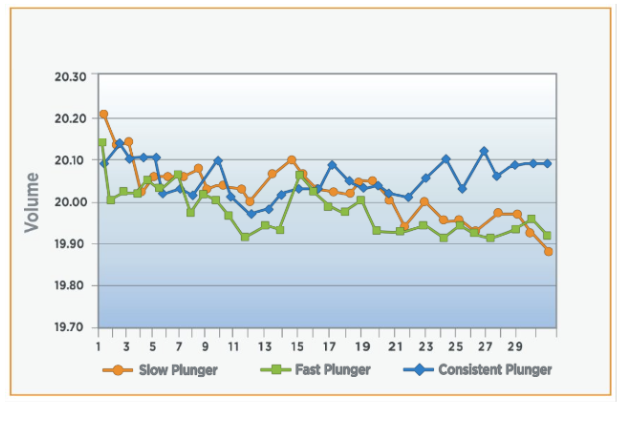

- Artel Liquid Handling Verification

- Anaerobic Jar Systems

- CSF Cell Counter

- Bilirubin Testing

- Dairy Testing

- Applications & Industries

- Service & Support

- Resources

- Company