Proper instrument calibration is important to prevent potential error sources from degrading the result. Several factors can occur during and after a calibration that can affect its result. Among these are:

Using the wrong calibrator values: It is important to closely follow the instructions for use during the calibration process. Disregarding the instructions and selecting the wrong calibrator values will “teach” the instrument incorrectly, and produce significant errors over the entire operating range. While many instruments have software diagnostics that alert the operator if the calibrators are tested in the incorrect order (i.e. Calibrator 2 before Calibrator 1), the instrument may accept one or more calibrators of the wrong value without detecting the operator error.

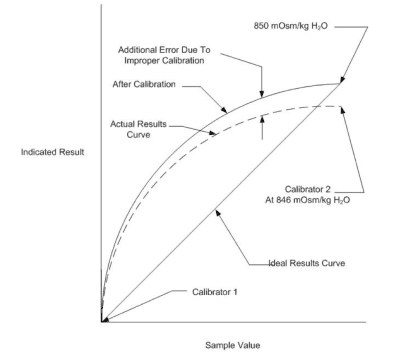

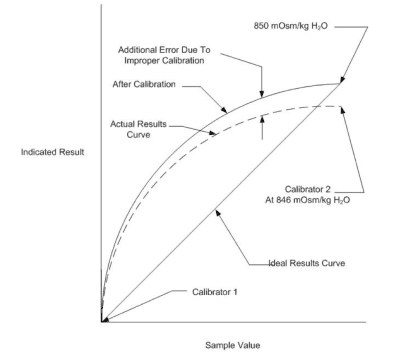

Calibrator formulation tolerance: It is important to use calibrators that are formulated to tight tolerance specifications by a reputable manufacturer. There is a tolerance associated with formulating a calibrator/control due to normal variations in the instrumentation and quality control processes. This tolerance can affect the mean value obtained when using the calibrator. For example, if the calibrators have nominal values of 50 and 850 mOsm/kg H2O, and were manufactured toward the low end of their allowable range, the net effect might be to lower the calibration curve by approximately several mOsm/kg H2O over the calibrated range. As an example, Figure 3 illustrates what can happen in a situation where Calibrator 2 is assumed to be at its nominal value, say 850 mOsm/kg H2O, when the true formulated value is 846. The calibration process “teaches” the instrument incorrectly that 846 is actually 850, thus raising the Actual Results curve higher than it would be if the instrument were “taught” that Calibrator 2 was 846 mOsm/kg H2O, or Calibrator 2 had an actual formulation value of 850 mOsm/kg H2O.

Sample preparation technique: As in the case of normal testing, good sample preparation technique is essential to obtaining the best performance from the calibration process. A similar situation to that depicted in Figure 3 can occur if good sample preparation techniques are not followed when providing the calibrator samples. Conditions such as pipeting different sample volumes, allowing air bubbles in the samples, or preparing the samples too early so that evaporation occurs, can all increase the variation in the results obtained from the calibrators tested in the calibration process. This increased variation can result in mean values for the calibrators that vary by several mOsm/kg H2O from what they should be, erroneously shifting the calibration curve, resulting in increased errors for all results.

Ambient temperature effects: It is important to periodically calibrate an instrument at a temperature close to that at which it will be operated. Even when a calibration is performed properly, there are other factors that can affect the accuracy of results. Environmental factors, such as the ambient temperature, can introduce errors that may not be readily evident when testing samples with unknown values. Components, such as electronics, used in an instrument may be affected by changes in operating temperature. If an instrument is calibrated at one temperature and then operated at a significantly different temperature, the temperature-induced error can also degrade the results’ accuracy.