Ratiometric Photometry

Ratiometric Photometry combined with Artel’s expertise in dye chemistry, metrology, and low-volume liquid handling provide the foundation for our extremely accurate and precise volume measurement systems. We saw the limitations of gravimetric, fluorometric, and single-dye photometric volume verification methods and responded by developing this fast, easy-to-use, and robust volume measurement method.

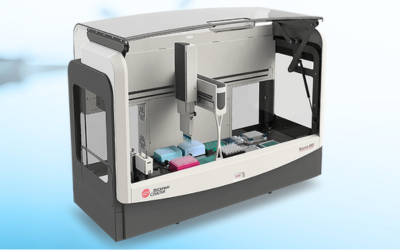

The Artel MVS conforms to Dual-Dye Ratiometric Photometric Method described in ISO 23783-2:2022, and the Ratiometric Photometric Method described in ISO/IWA 15:2015 for automated liquid handling systems. It can be used to fulfill test and calibration requirements of handheld multichannel pipettes according to ISO 8655-7:2022. The MVS can be used to fulfill test and calibration requirements of handheld or automated liquid handling systems according to CLSI QMS23:2019, ISO 17025:2017, cGMP, and cGLP. ArtelWare Software can be used in laboratories compliant to 21 CFR Part 11.

The Artel PCS conforms to the Dual-Dye Ratiometric Photometric Method described in ISO 8655-7:2022 and facilitates conformity to the Photometric Reference Measurement Procedure described in ISO 8655-8:2022. The PCS can be used to fulfill test and calibration requirements according to CLSI QMS23:2019, ISO 17025:2017, cGMP, and cGLP. ArtelWare Software can be used in laboratories compliant to 21 CFR Part 11.

Applying the Beer-Lambert Law

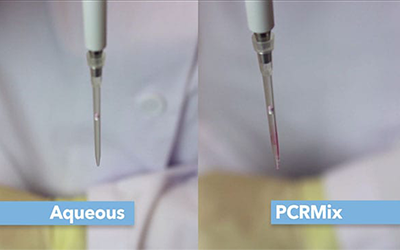

Our volume verification systems use dual-dye, dual-wavelength absorbance measurements to determine a target volume of sample solution dispensed from a pipette or liquid handling system. Two dyes, with distinct absorbance maxima at 520 nm (red) and 730 nm (blue), make this measurement possible.

Volume measurements are determined by applying the Beer-Lambert Law, which states that the measured absorbance of a dye (A) is proportional to the product of the concentration of the dye (C, g L-1), the molar absorptivity of the dye (ε, L g-1 cm-1), and the pathlength of the sample holder (ℓ, cm).

A = ε ℓ C

Given the closely controlled concentrations (C) and known molar absorptivities (ε) of the dyes in Artel Sample Solutions, the Beer-Lambert Law can be used to determine the pathlength traversed by a light beam in the MVS system by solving for ℓ in the equation above.

From the pathlength and knowledge of the dimensions of the container (microtiter plate well), we can calculate the total volume of the dispensed solution. By measuring a second dye at a different wavelength and applying ratiometric principles (see Benefits, below), we obtain greater measurement accuracy, and can accurately measure volumes as small as 10 nL (0.010 μL).

Benefits

Ratiometric photometry and measurements conducted with Artel’s dye solutions provide measurement of small liquid volumes with a high degree of accuracy traceable to the International System of Units (SI).

The ratiometric method is a refinement of photometry designed to overcome the accuracy limitations of traditional single-dye photometric volume measurements by employing two standardized dyes and absorbance readings in pairs that can be combined into absorbance ratio readings.

The ratio of absorbances measured with the same instrument at the same time is more accurate than individually measured absorbances—errors introduced to one measurement from sources such as optical imperfections, pathlength variation, and photometer non-linearity are introduced to both measurements, allowing one error to offset the other in the ratio. This leads to a higher degree of accuracy and precision in ratiometric methods versus traditional single-dye photometric methods. This self-cancelling of errors enables outstanding accuracy in measurement of small volumes.

In contrast to fluorescence-based methods, ratiometric photometry provides traceable accuracy and precision measurements by using one dye as an internal standard and a second as the sample. Compared to gravimetry, ratiometric photometry offers greater speed, ease-of-use, independence from environmental affects, and enhanced accuracy at small volumes.1,2

The PCS and MVS make ratiometric measurement easy and traceable with standardized dye solutions and sophisticated software to automate calculations and data management. But beyond ease-of-use, they provide peace-of-mind, enabling consistent, comparable data from different liquid handlers at different sites. The PCS and MVS provide a global standard for liquid handling measurement.

1. Bradshaw, J. T. & Albert, K. J. in Pr. Approaches Method Valid. Essent. Instrum. Qualif. (Chan, C. C., Lam, H. & Zhang, X. M.) 347–375 (John Wiley & Sons, Inc., 2010). at <http://onlinelibrary.wiley.com/doi/10.1002/9780470630716.ch15/summary>

2. Rodrigues, G. & Curtis, R. in Pr. Approaches Method Valid. Essent. Instrum. Qualif. (Chan, C. C., Lam, H. & Zhang, X. M.) 327–346 (John Wiley & Sons, Inc., 2010). at <http://onlinelibrary.wiley.com/doi/10.1002/9780470630716.ch14/summary>